JR Series Wound Rotor Three-phase Asynchronous Motor

Introduction:

JR series motor is wound rotor three-phase asynchronous motor. It meet the standard of JB 564-64 technical requirements. JR series must insert starting rheostat in rotor circuit in advance, and can’t be started directly by short circuiting the rotor winding. The basic mounting mode of this type is horizontal installation with bottom foot. It should be connected with the driven machine by coupler device. JR motor adopted a double – sided radial ventilation system and antifriction bearing. By the side of shaft extension end, the outlet box is on the right of the frame. It can be reduced power running for long time in condition of reduce the torque.

Application:

Slip ring lifting, Ventilator, compressor, water pump, crusher, ball mill, stock-removing machine, transport machine and other machinery.

It can be prime mover of industries like coal mine, mechanical industry, power station and different kinds of manufacturing and mining industries.

Operation Condition:

Ambient temperature: -15°C≤θ≤40°C

Altitude: not exceed 1000m

Rated voltage:380V

Rated frequency: 50Hz, 60Hz

Protection: the main body of the motor is IP54, but

The terminal box reaches IP55

Insulation class: F,H

Cooling method: IC0141

Duty: S1(continuous)

The Meaning of the Models:

JR 115 -6

JR— Wound rotor asynchronous motors

11—Center height of frame

5—Core Length

6—Pole number

Note: JR series motor has two types: brushes lifting with short-circuiting device and brushless lifting with short-circuiting device.

Technical Parameter:

| Type | Rated Power

(KW) |

Voltage

(V) |

Rated Value | Max torque

———— Rated torque |

Rotor Voltage

(V) |

Rotor Current(A) | Rotor Flywheel Moment

(N·m2) |

Weight

(kg) |

|||

| Speed | Stator current | Efficiency | Power factor | ||||||||

| r/min | A | % | cosφ | ||||||||

| JR114-4 | 115 | 380 | 1450 | 212 | 91 | 0.904 | 2 | 173 | 433 | 160 | 1035 |

| JR115-4 | 135 | 1460 | 246 | 92.1 | 0.904 | 2.33 | 210 | 408 | 180 | 1130 | |

| JR116-4 | 155 | 1460 | 278 | 92.7 | 0.913 | 2.28 | 238 | 412 | 200 | 1200 | |

| JR117-4 | 180 | 1460 | 321 | 93.1 | 0.911 | 2.45 | 275 | 409 | 220 | 1270 | |

| JR126-4 | 225 | 1470 | 405 | 93.1 | 0.907 | 2.2 | 291 | 488 | 370 | 1660 | |

| JR127-4 | 260 | 1472 | 461 | 93 | 0.92 | 2.18 | 334 | 493 | 400 | 1760 | |

| JR128-4 | 300 | 1475 | 530 | 93.9 | 0.917 | 2.37 | 390 | 482 | 440 | 1890 | |

| JR136-4 | 220 | 6000 | 1475 | 26 | 91.7 | 0.894 | 1.97 | 307 | 457 | 590 | 2110 |

| JR137-4 | 260 | 1480 | 30.3 | 92.3 | 0.897 | 1.92 | 346 | 481 | 630 | 2210 | |

| JR138-4 | 300 | 1478 | 35 | 92.4 | 0.9 | 1.96 | 398 | 483 | 710 | 2320 | |

| JR147-4 | 360 | 1479 | 41 | 93.1 | 0.904 | 2.68 | 558 | 406 | 850 | 3000 | |

| JR148-4 | 440 | 1475 | 49 | 93.44 | 0.92 | 2.68 | 634 | 410 | 1000 | 3300 | |

| JR1410-4 | 500 | 1482 | 55.5 | 94.1 | 0.92 | 2.44 | 717 | 420 | 1200 | 3600 | |

| JR158-4 | 680 | 1480 | 77.8 | 93.8 | 0.87 | 2.7 | 722 | 586 | 1700 | 4500 | |

| JR 1510-4 | 850 | 1483 | 95.9 | 94.3 | 0.904 | 2.5 | 803 | 657 | 2100 | 4700 | |

| JR 1512-4 | 1050 | 1480 | 118 | 94.4 | 0.9 | 2.3 | 1035 | 630 | 2500 | 5450 | |

| JR115-6 | 75 | 380 | 965 | 142 | 90.3 | 0.89 | 1.98 | 127 | 382 | 210 | 1025 |

| JR 116-6 | 95 | 970 | 177 | 91.74 | 0.891 | 2.33 | 162 | 371 | 240 | 1115 | |

| JR 117-6 | 115 | 973 | 213 | 92.1 | 0.893 | 2.32 | 191 | 381 | 260 | 1170 | |

| JR125-6 | 130 | 976 | 245 | 91.4 | 0.882 | 1.87 | 187 | 445 | 400 | 1450 | |

| JR 126-6 | 155 | 977 | 294 | 91.1 | 0.873 | 1.85 | 219 | 455 | 440 | 1530 | |

| JR 127-6 | 185 | 977 | 334 | 92.8 | 0.907 | 2.27 | 366 | 319 | 490 | 1560 | |

| JR 128-6 | 215 | 979 | 385 | 93.3 | 0.908 | 2.44 | 424 | 317 | 540 | 1630 | |

| JR136-6 | 240 | 977 | 436 | 93 | 0.905 | 1.85 | 407 | 376 | 760 | 1970 | |

| JR 137-6 | 280 | 981 | 507 | 93.14 | 0.907 | 2.15 | 490 | 360 | 840 | 2030 | |

| JR148-6 | 310 | 6000 | 983 | 36.8 | 91.99 | 0.88 | 2.2 | 505 | 374 | 1650 | 3360 |

| JR 1410-6 | 380 | 983 | 44.7 | 92.5 | 0.88 | 2.1 | 590 | 391 | 1850 | 3630 | |

| JR 157-6 | 460 | 985 | 54 | 92 | 0.87 | 2 | 568 | 517 | 2300 | 3700 | |

| JR 158-6 | 550 | 985 | 64 | 92.5 | 0.87 | 2 | 618 | 570 | 2600 | 4000 | |

| JR 1510-6 | 650 | 985 | 75 | 93 | 0.87 | 2.1 | 741 | 560 | 3300 | 4500 | |

| JR 1512-6 | 780 | 985 | 89 | 93.5 | 0.88 | 2.2 | 862 | 570 | 4000 | 4750 | |

| JR115-8 | 60 | 380 | 720 | 120 | 89.38 | 0.846 | 2.59 | 172 | 230 | 250 | 980 |

| JR 116-8 | 70 | 723 | 137 | 90.27 | 0.856 | 2.57 | 199 | 225 | 280 | 1060 | |

| JR 117-8 | 80 | 723 | 154 | 90.96 | 0.869 | 2.45 | 222 | 230 | 310 | 1135 | |

| JR125-8 | 95 | 725 | 183 | 90.55 | 0.867 | 1.89 | 213 | 292 | 450 | 1380 | |

| JR126-8 | 110 | 726 | 212 | 90.75 | 0.866 | 1.84 | 243 | 294 | 510 | 1550 | |

| JR127-8 | 130 | 728 | 242 | 92.15 | 0.88 | 2.04 | 256 | 324 | 570 | 1500 | |

| JR128-8 | 155 | 732 | 291 | 92.54 | 0.875 | 2.3 | 309 | 316 | 640 | 1600 | |

| JR136-8 | 180 | 735 | 345 | 92.25 | 0.858 | 2 | 354 | 323 | 770 | 1850 | |

| JR137-8 | 210 | 734 | 400 | 93 | 0.86 | 1.84 | 394 | 341 | 850 | 1940 | |

| JR138-8 | 245 | 734 | 453 | 93.1 | 0.86 | 1.8 | 425 | 365 | 850 | 2060 | |

| JR147-8 | 200 | 6000 | 738 | 25.7 | 91.6 | 0.818 | 2.5 | 406 | 299 | 1500 | 3090 |

| JR148-8 | 240 | 738 | 30.6 | 92 | 0.821 | 2.43 | 457 | 319 | 1650 | 3300 | |

| JR1410-8 | 280 | 740 | 35.7 | 92.3 | 0.818 | 2.55 | 550 | 309 | 1850 | 3600 | |

| JR157-8 | 320 | 739 | 39 | 92.5 | 0.86 | 2.2 | 509 | 395 | 2300 | 3700 | |

| JR158-8 | 380 | 738 | 45.6 | 93 | 0.86 | 2.22 | 547 | 436 | 2600 | 4000 | |

| JR1510-8 | 475 | 738 | 56 | 93.28 | 0.856 | 2.031 | 641 | 468 | 3300 | 4500 | |

| JR1512-8 | 570 | 738 | 66.9 | 93.72 | 0.86 | 1.981 | 698 | 514 | 4000 | 4750 | |

| JR115-10 | 45 | 380 | 577 | 97 | 88 | 0.8 | 2.21 | 117 | 252 | 260 | 950 |

| JR116-10 | 55 | 577 | 116 | 89 | 0.805 | 2.17 | 140 | 256 | 280 | 1040 | |

| JR117-10 | 65 | 577 | 135 | 89 | 0.81 | 2.16 | 159 | 263 | 310 | 1110 | |

| JR125-10 | 80 | 574 | 164 | 90.15 | 0.817 | 1.96 | 168 | 309 | 460 | 1350 | |

| JR126-10 | 95 | 573 | 193 | 90.44 | 0.825 | 1.83 | 188 | 326 | 520 | 1440 | |

| JR127-10 | 115 | 575 | 233 | 90.9 | 0.82 | 1.92 | 225 | 328 | 580 | 1590 | |

| JR128-10 | 130 | 575 | 261 | 91.14 | 0.826 | 1.83 | 251 | 333 | 650 | 1720 | |

| JR137-10 | 155 | 583 | 307 | 91.45 | 0.854 | 2 | 354 | 280 | 930 | 1920 | |

| JR138-10 | 180 | 583 | 346 | 91.6 | 0.86 | 1.8 | 387 | 300 | 1050 | 2090 | |

| JR1410-10 | 200 | 6000 | 590 | 27 | 90.5 | 0.8 | 2.7 | 511 | 248 | 2100 | 3300 |

| JR157-10 | 260 | 588 | 33.5 | 91.2 | 0.81 | 2.1 | 412 | 406 | 3000 | 3700 | |

| JR158-10 | 310 | 585 | 39.5 | 91.7 | 0.81 | 2 | 442 | 454 | 3400 | 4000 | |

| JR1510-10 | 400 | 585 | 50.3 | 92 | 0.82 | 2.2 | 554 | 467 | 4200 | 4500 | |

| JR1512-10 | 480 | 585 | 60 | 92.9 | 0.81 | 2.3 | 602 | 512 | 5100 | 4750 | |

| JR1510-12 | 280 | 490 | 38 | 91.4 | 0.77 | 2.2 | 478 | 380 | 4200 | 4500 | |

| JR1512-12 | 330 | 490 | 44 | 91.7 | 0.78 | 2.1 | 515 | 413 | 5100 | 4750 | |

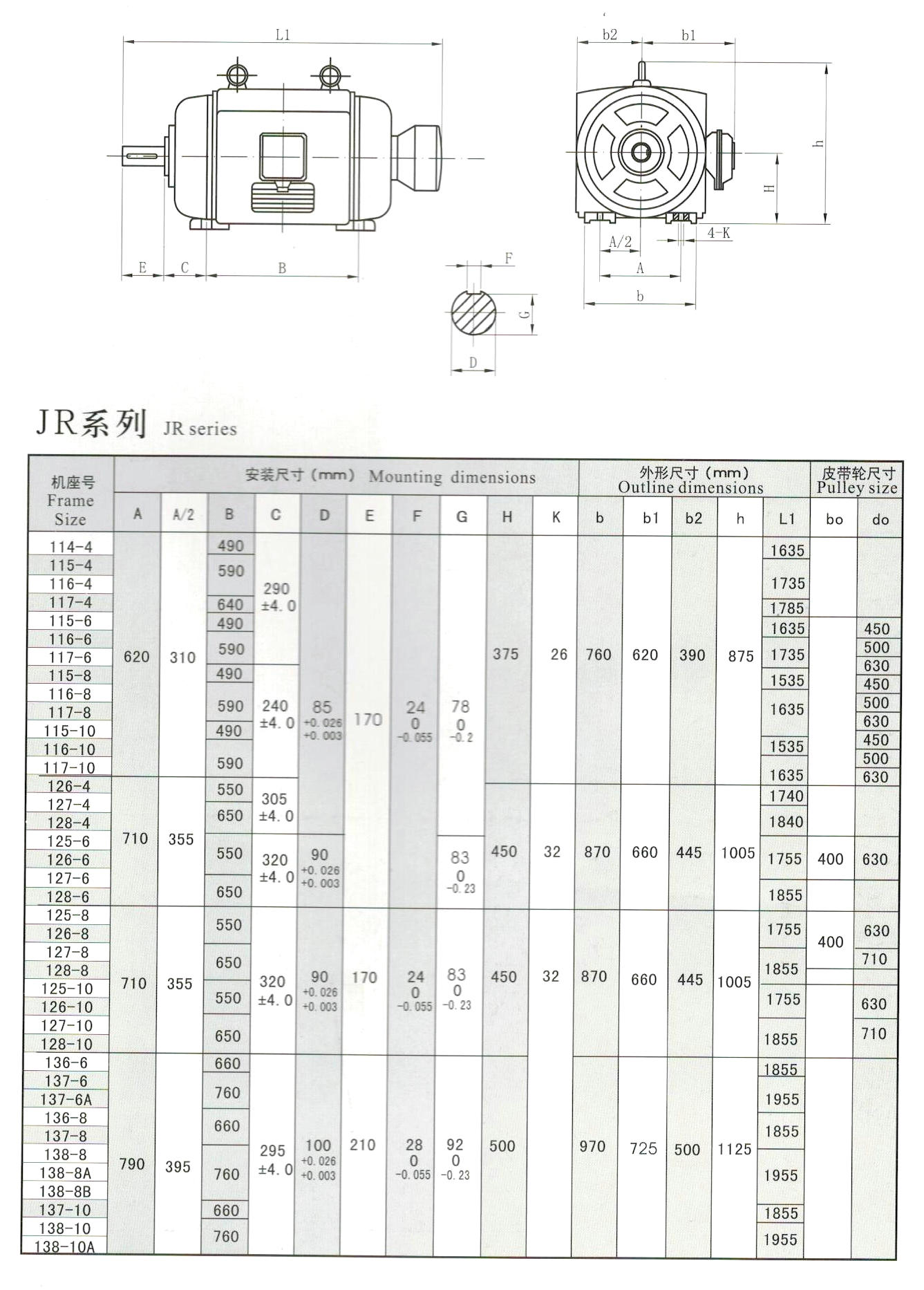

Dimension: