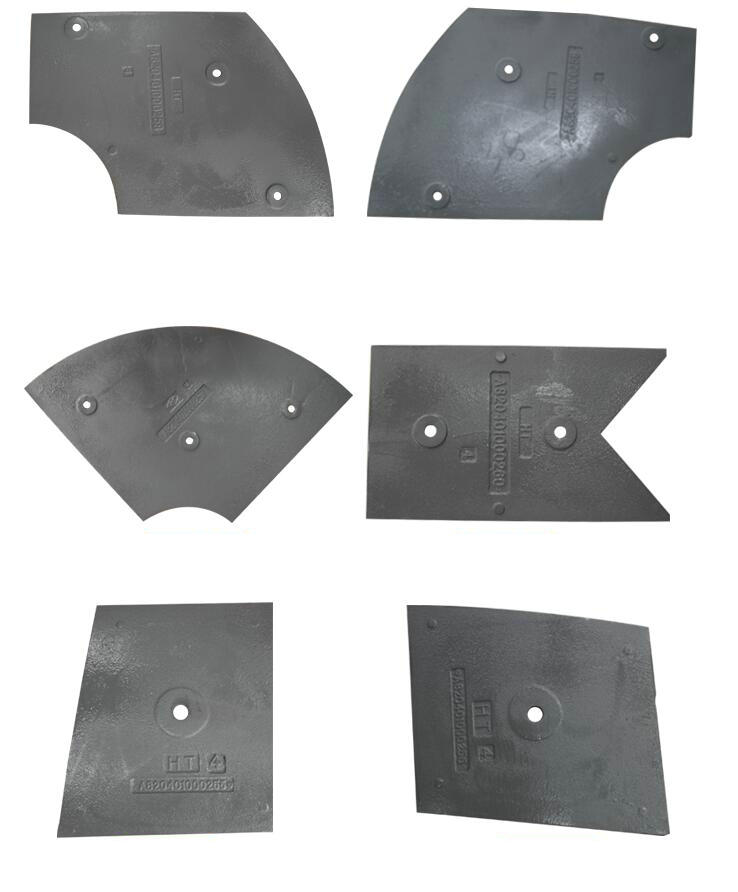

Mixer Liner

The mixer liner is used to protect the cylinder from the direct impact and friction of the grinding body and material. At the same time, different types of liner can be used to adjust the movement state of the grinding body to enhance the grinding effect of the grinding body on the material. It helps to improve the grinding efficiency of the mill, increase the output and reduce the metal consumption.

The main considerations for selecting various liners are the lifting effect on the grinding medium, the running trajectory of the medium, and the working conditions.

The main liner materials are: medium carbon medium chromium, medium carbon medium chromium, medium carbon low alloy, low carbon high alloy, chrome molybdenum nickel alloy steel, 90 chrome alloy steel, ordinary high strength steel, modified high manganese steel, super High manganese steel, heat resistant steel, high chromium cast iron, high chromium cast steel.

When it is mainly for pulverization, the liner is required to have a strong pushing ability for the grinding body, and the lining plate should have good impact resistance. The high manganese steel ZGMn13 has sufficient impact toughness, but is not wearable and easily deformed. Most have chosen alloy steel or chrome-molybdenum alloy steel liners in the dual-medium quenching process. Comparing these several kinds of wear-resistant materials, the alloy steel has better performance and long service life.

Other mixer ware parts: