The Operating Instruction of Concrete Mixing Plant HZS120

Ⅰ. Introduction

HZS120 is a new type of concrete mixing plant. Its mainframe machine is Double Horizontal Shaft Concrete Mixer JS2000, and its automatic control system is composed of IPC (Industrial Personal Computer) and Programmable Controller. Through this system, various ratio of concrete can be mixed, with the average hourly productivity of 120m3/h and discharge height of 3.8m. HZS120 is suitable for medium scale engineering constructions of hydropower, highway, bridge, port, airport, ect., and the large and medium-sized concrete precast factories and commodity concrete production factories.

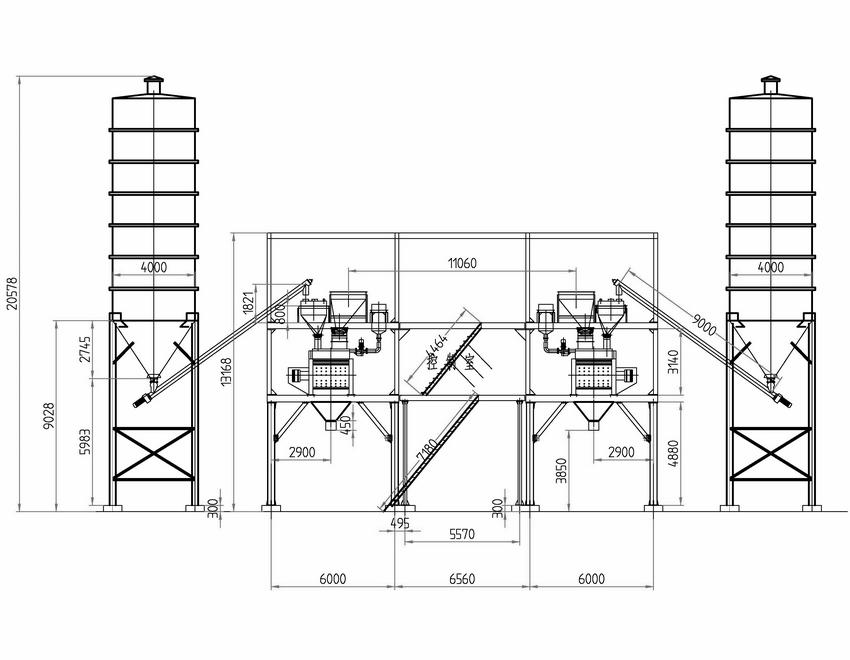

Concrete Mixing Plant HZS120 consists of many different parts, such as aggregate batching system, material conveying system, measurement system, stirring device, water supply system, additives supply system, pneumatic system and electric control system. The process is: the screw conveyor transports cement and fly ash in the cement silo into the weighing hopper; and the sand and stone in the aggregate hopper are put onto the horizontal belt conveyor through the arc door under the silo to have a weigh, and then, they are sent into the bin by the horizontal and inclined belt conveyor; the electric pump sends water and additives into their respective weighing hopper. Then, put all the batching into the mixer and mix the concrete. At last, discharge the mixed concrete into the transferring truck through the collecting hopper.

HZS120 is reliable and accurate. The mixed time is short and the quality is good. It has two methods of operation, manual and automatic method. HZS 120 can save 200 kind of concrete formulation, and be equipped with the printer, which is very convenient for production management.

To operate the plant correctly and improve the work efficiency greatly, the workers must read the full set of instructions carefully, and be trained before operating HZS 120.

HZS 120 Executive Standard: GB10172-88.

Our factory has established and implemented the quality system consistent with GB/T19001-2000-ISO9001:2000 standard.

Ⅱ. Main Technical Parameters

- Productivity 120 m3/h

- Discharge Height 3800 mm

- Mixer

Model JS2000

Discharging Capacity 2 m3

Motor Power 37X2 KW

Aggregate Size (gravel/ pebble) 40/60

- Weighing System

Stone: Equipment electronic scale

Metering Capacity 50—2500kg

Metering Mode Single Measurement

Sand: Equipment electronic scale

Metering Capacity 50—2500kg

Metering Mode Single Measurement

Cement: Equipment trolley balance

Metering Capacity 20—1200kg

Metering Mode two materials accumulated

Metering Accuracy 1%

Fly ash: Equipment trolley balance

Metering Capacity 10—500kg

Metering Mode Single Measurement

Metering Accuracy 1%

Admixture: Equipment trolley balance

Metering Capacity 5—300kg

Metering Mode Single Measurement

Metering Accuracy 1%

Water: Equipment trolley balance

Metering Capacity 10—500kg

Metering Mode Single Measurement

Metering Accuracy 1%

Additive: Equipment trolley balance

Metering Capacity 1—70kg

Metering Mode two materials accumulated

Metering Accuracy 1%

- Material Conveying Apparatus

Horizontal Belt Conveyor

Width 1000 mm

Speed 1.6 m/s

Length 16000 mm

Motor Power 11 kW

Inclined Belt Conveyor

Width 1000 mm

Speed 1.8 m/s

Length 39668 mm

Obliquity 230

Motor Power 11 kW

3 Cement Screw Conveyors

Length 11430、 9640、 10480 mm

Diameter 323 mm

Obliquity 260 31.30 28.60

Productivity 100t/h

Motor Power 18.5kW

1 Fly Ash Screw Conveyor

Length 9060 mm

Diameter 273 mm

Obliquity 32.30

Productivity 80t/h

Motor Power 15kW

1 Admixture Screw Conveyor

Length 8060 mm

Diameter 219 mm

Obliquity 37.10

Productivity 50t/h

Motor Power 9.2kW

- Water Supply System

Pump IS80-65-125

Flow 50m3/h

The Maximum Head 20000mm

Power 5.5 kw

- Additives Supply System

Pump FB40-32-20

Flow Rate 6.3m3/h

The Maximum Head 20000mm

Power 0.75X2 kw

- Pneumatic System

2 Air Compressors w-1.0

Displacement 1.0 m3/min

Pressure 0.7 Mpa

Power 7.5X2KW

- Sand and Stone Storage Bin

Bin Capacity 4X25 m3

Sorts of Sand and Stone 4 ( 3 for stone and 1 for sand)

- Cement Silo ( 5 sets in total ) 200tx3+100t+50t

- Electric Control System

Power Source: 3 phase 4 wire 380 V, 50Hz;

Power Supply: Transformer. The capacity is not less than 500KVA.

Methods of Operation: manual control and automatic computer control. It can preset 200 kind of concrete formulation.

- Total Installation Power 210 KW

- Total Weight ( without the silo) About 72 t

- Prime Overall Size ( L W H ) 6400x5400x13000mm