DISCHARGE DOOR HYDRAULIC PUMP

I. DISCHARGE DOOR:

Composed by discharge door and bearing. The gap between the mixing tank and the dicharge door

should be within 1-1.5mm. The discharge door should be cleaned periodically to prevent concrete

accumulation and ensure a smooth door operation.

II. HYDRAULIC CYLINDER:

Liner motion tank (single hydraulic cylinder), which is driven by hydraulic oil powered by hydraulic

pump through pressure-proof hoses.

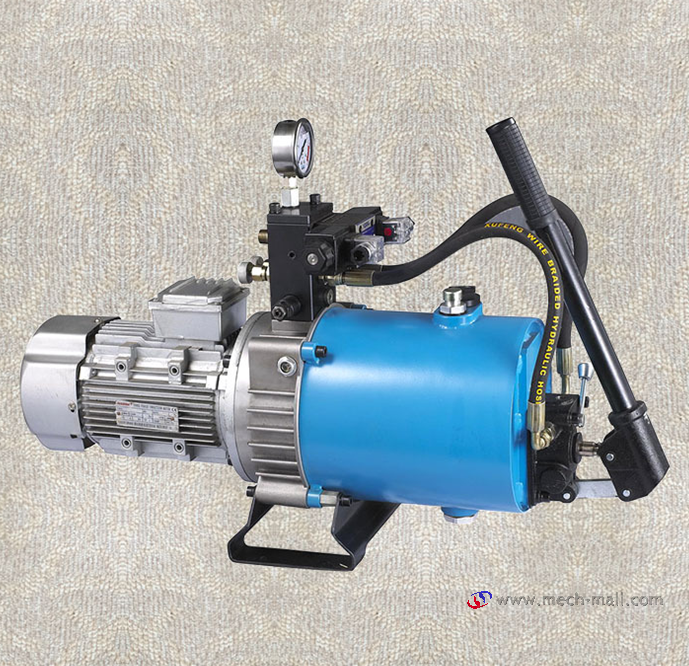

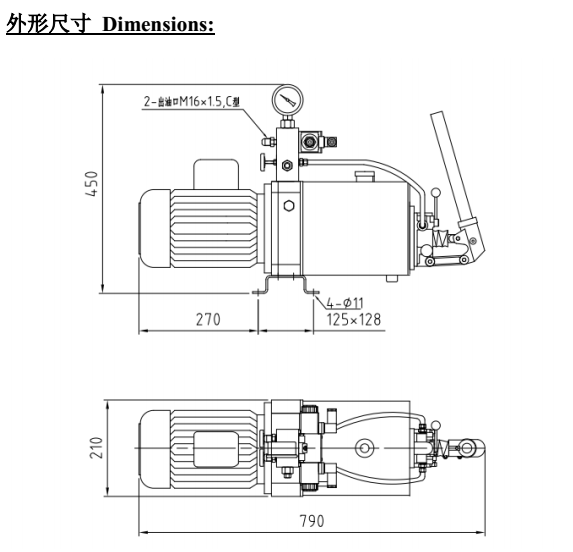

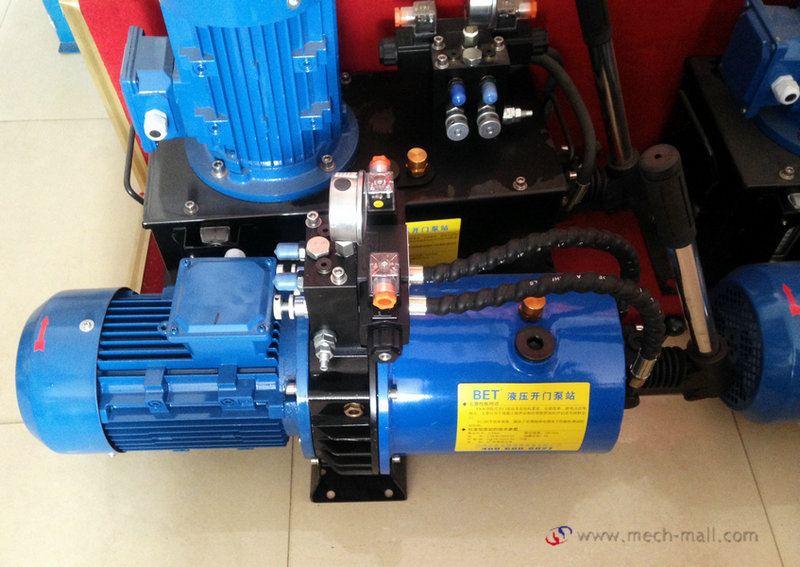

III. HYDRAULIC PUMP:

Discharge door hydraulic powerpack is composed of motor, pump, cylinder, manual pump, dividing

valve, etc.. The hydraulic system shall work only at unloading phase. It shall not continuously work for

a long time. On power cut or emergency, it can be operated manually for urgent unloading.

Pressing the opening pushbutton, the correspondent solenoid in the solenoid valve is excited and the

pump stop is operated by the opening micro-switch placed on the discharge door rotation axis. Pressing

the closing pushbutton, the correspondent solenoid in the solenoid valve is excited and the pump stop

is operated by a pressure switch placed on the circuit. The closing micro-switch has to be used only to

indicate the position of the door and activate any automatic devices required. The motor of the pump

stops at each cycle end.

When changing the oil, completely drain the system including hoses to one or more cylinders.

| Consumption(L) | Positon | Oil Type | Oil Model | ||

| 0.75~1. 5m3 |

2.0 m3 |

3.0~5.0 m3 |

|||

| Discharge Door Hydraulic Oil Pump |

Anti-wearing Hydraulic Oil |

8(L) | 10(L) | 18(L) | D GT BE46# 24# |