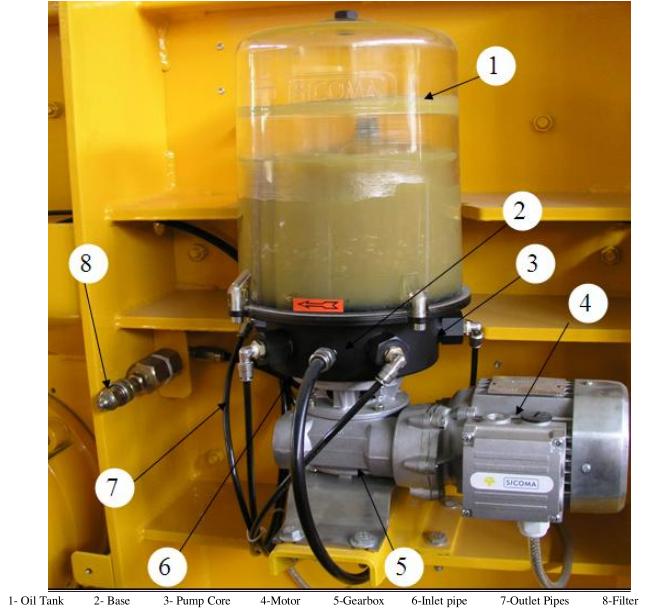

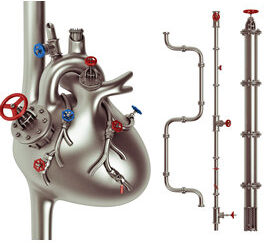

LUBRICATION SYSTEM

Lubrication is one of the core parts of a mixer. Its operation directly affects the mixer’s efficiency and life. To make your mixer to operate safely and efficiently, please ensure proper maintenance and operation of the lubrication system.

TECHNIC DATA

◆ PUMP

Working Temp:-25℃~70℃

Outlet Qty:4

Tank Volume:4L

Oil Feeding:Through Oil Feeding Filter

Lubricant:Maximum Grade NLGI 2

Protection:IP6K 9K acc. To DIN 40050 T9

◆ MOTOR

Working Voltage.:380VAC/50Hz

Maximum Output Power.:90W

Rotation Speed:1350rpm

Notice: The motor is intermittent rotating.

OPERATION

This is automatic lubricating system. The lubricating pump is set to work synchronous with mixer

before delivery and is controlled by relay, which stops for 10 min after 5 min working to save grease

consumption. Under normal working condition, user only need to periodically check and fill the grease

and doesn’t need to operate manually.

◆Check

Check every day if the grease is lubricating the seal ends. Procedure is as follows:

There is one spare grease nozzle on the 4 seal ends. Press the nozzle core by nail. If there is grease coming out, the pump is working properly. If there is grease lack, please check if the seal end pipe is unobstructed. Check again if the dividing valve is blocked. Finally, check if the valve cores are working properly. Solutions: If the grease pump system is broken or in repair while the mixer needs to be working, feed the grease from the 4 nozzles by a grease gun. (≥2 times a day);

Grease pump must be lubricated by clean lubricant, which should be injected through the filter. Grease is not allowed to be filled from the tank top as it would cause pump core

damage. Grease shall contain no impurities and keep a constant density.

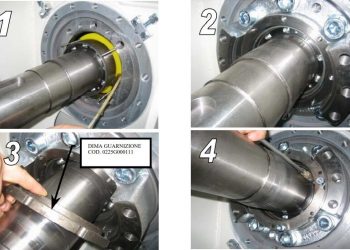

◆ PUMP CORE

Lubricant Output:6.2cm 3 /min

Maximum Working Pressure:150bar

Connection Cable:G 1/4

Pipe Diameter:φ6mm

MAITENANCE

the best time for maintenance is when the lubricant is being refilled.

Check if the pipe is OK. If it is damaged, replace immediately.

Gas cleaning system is recommended. Tri, Per or any similar chemical solvent is forbidden. Neither polar organic solvent can be used, such as alcohol, carbinol, propanol ect.

TROUBLESHOOTING

Error:Motor doesn’t work Reason and Solution:

Power Voltage supply is cut:1. Check the line and fuse. Replace the fuse if necessary.

2. Check the line between fuse and pump plug.

Motor failure: Check the line between power and motor. Replace the motor if necessary.

Pump cannot work Reason and Solution:

No lubricant in the tank:

Fill the clean lubricant into the tank. Power the pump till the lubricant reaches the parts.

Notice: As the ambient temp is different, the pump can only reach the maximum lubricant output only after working for 10 minutes;

Bubble in the lubricant: Loose the accessories of the safety valve. Leave no bubble in the lubricant;

Unqualified lubriant is used: Replace the lubricant

Pump core is blocked: Disassemble the pump. Check if there are any impurities and clean.

Pump piston is worn: Replace pump core

Pump core one-way valve is damaged or blocked: Replace pump core