GP15-60 Traversing Drive

Application Scope

- Widely used in wire and cable, textile, plastic products, rope production and other industries, evenly lined into a loop of fried wire and rewind into a disk.

- The wire passes through the wire wheel or the wire roller on the traversing drive, adjusts the wire pitch as required, and evenly and reciprocally wound onto the take-up reel.

- The opening and the pitch of the cable are within the specified range, and can be adjusted arbitrarily to meet the process requirements of the collection and distribution line.

Advantages

- Stepless speed regulation: The receiving shaft transmits a certain speed to the plain shaft. Without changing the speed of the plain shaft, just dialing the indicator on the dial can adjust the speed of the coil reciprocating motion in the direction of the rod axis. The value can be set from 0 to the maximum pitch.

- Instantaneous commutation: There is no need to change the direction of rotation of the plain shaft. When the movable arm reversing wheel hits the block, the direction of travel of the cable aligner can be changed instantaneously, and the commutation time is not less than 1 second.

- High-speed cable: The linear motion of the traversing drive on the plain shaft can reach 4 m / s, which can meet the requirements of high cable speed and frequent commutation.

- Release device: Loosen the release lever without stopping the machine, and hold the traversing drive at any position on the plain shaft. (For example, the cable starts working from the end)

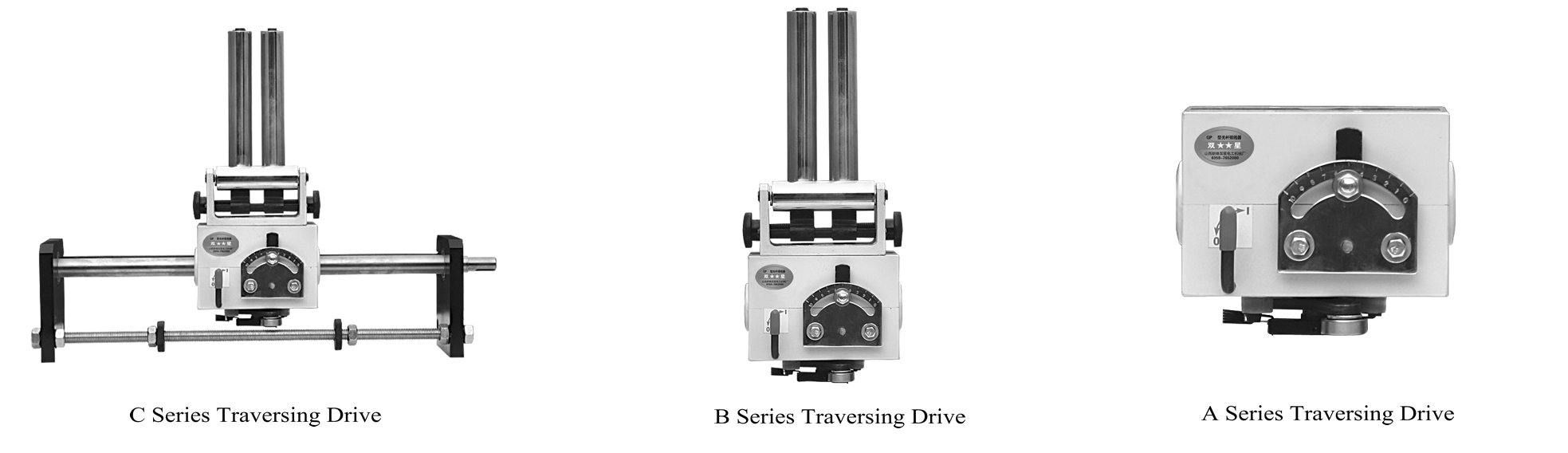

Model Description

A Series Traversing Drive : main unit

B Series Traversing Drive: main unit + wire roller or wire wheel

C Series Traversing Drive: main unit + wire roller or wire wheel + plain shaft + Bracket Plate + screw rod + guide rail = Assembly

Main Parameters and Assembling Diagram

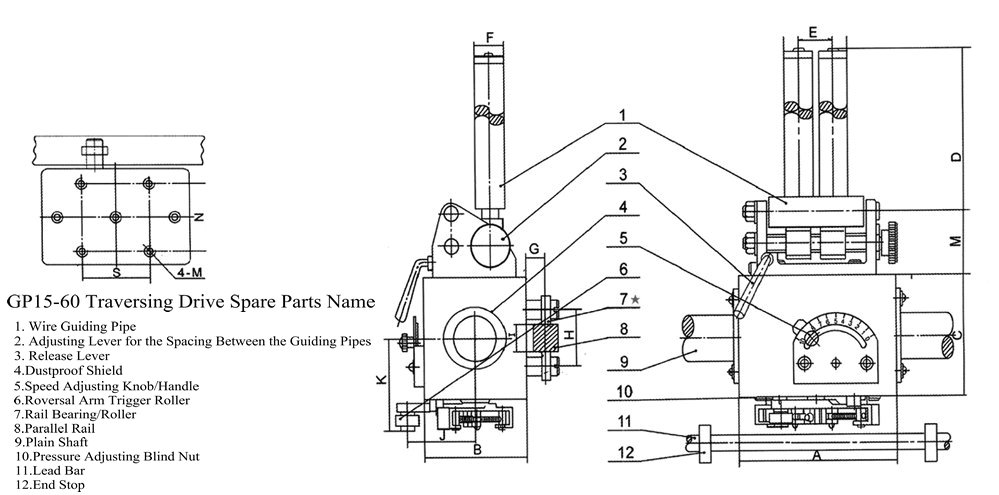

| Model | AXBXC | D | E | F | G | H | I | J | K | M | S | N | 4-M | Thrust

N |

Weight

Kg |

Travel Pitch |

| GP15 | 90X50X66 | 14 | 38 | 18 | 27 | 48 | 30 | 34 | 4-M6 | 100 | 1.2 | 0.1-11 | ||||

| GP20 | 123X71X85 | 150 | 30-60 | 25 | 14 | 40 | 18 | 35 | 62 | 50 | 40 | 42 | 4-M6 | 135 | 2.5 | 0.1-16 |

| GP30 | 141X87X105 | 150 | 30-60 | 25 | 14 | 46 | 20 | 65 | 76 | 50 | 60 | 62 | 4-M6 | 265 | 8.5 | 0.1-25 |

| GP40 | 165X106X121 | 250 | 30-70 | 32 | 26 | 56 | 28 | 70 | 82 | 60 | 60 | 62 | 4-M8 | 420 | 11.2 | 0.5-32 |

| GP50 | 220X132X160 | 400 | 40-95 | 38 | 35 | 70 | 36 | 90 | 116 | 85 | 90 | 104 | 4-M8 | 700 | 33 | 0.5-40 |

| GP60 | 240X150X182 | 460 | 40-120 | 38 | 35 | 70 | 36 | 90 | 130 | 90 | 104 | 110 | 4-M8 | 1200 | 42 | 0.5-48 |

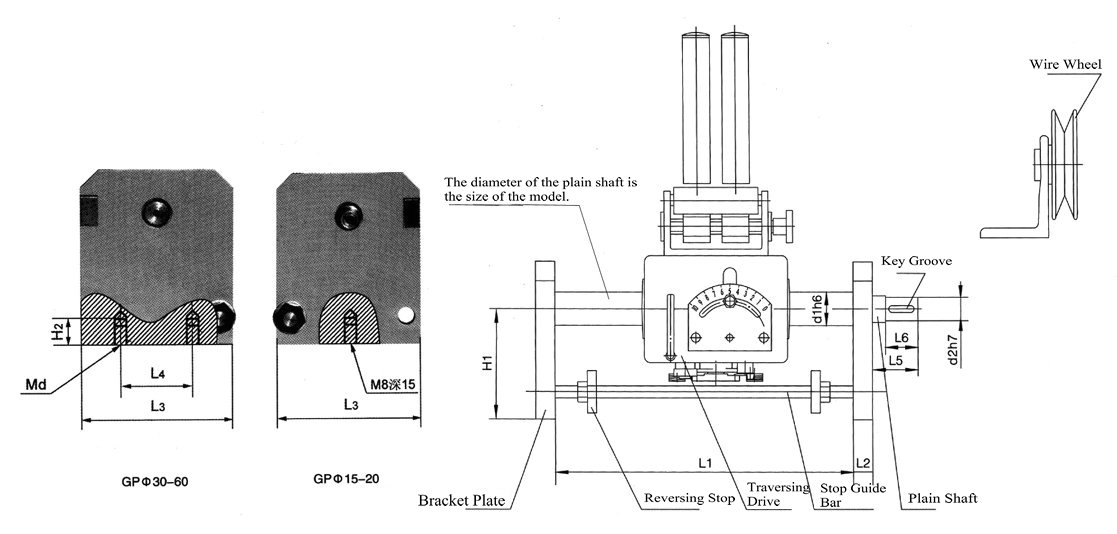

C Series Parameters and Assembling Diagram

| Model | d2 | L1 | L2 | L3 | L4 | L5 | L6 | H1 | H2 | Md | Key Groove (W X D) |

| GP15 | Ф15 | 450 | 14 | 70 | 40 | 75 | 15 | M8 | 5X2.5 | ||

| GP20 | Ф14 | 450 | 14 | 102 | 40 | 41 | 30 | 90 | 15 | 2-M8 | 5X2.5 |

| GP30 | Ф20 | 500 | 16 | 136 | 60 | 54 | 40 | 105 | 20 | 2-M10 | 6X3 |

| GP40 | Ф25 | 800 | 20 | 148 | 80 | 47 | 40 | 117 | 25 | 2-M10 | 8X4 |

| GP50 | Ф35 | 1000 | 22 | 220 | 130 | 58 | 40 | 160 | 25 | 2-M10 | 10X5 |

| GP60 | Ф45 | 1200 | 25 | 220 | 150 | 58 | 40 | 180 | 25 | 2-M10 | 10X5 |