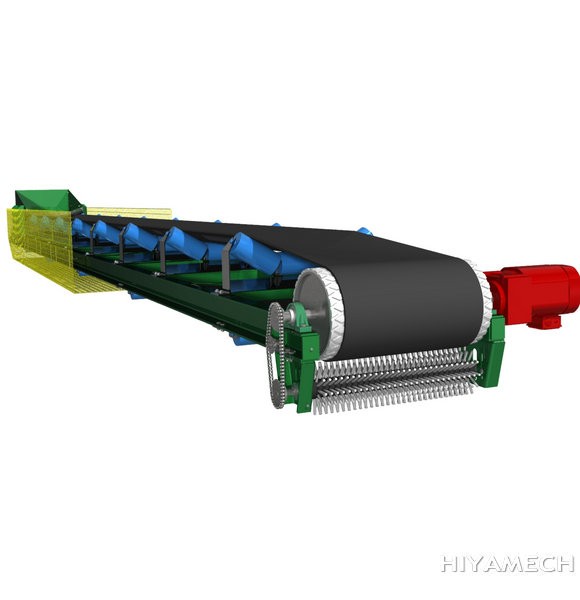

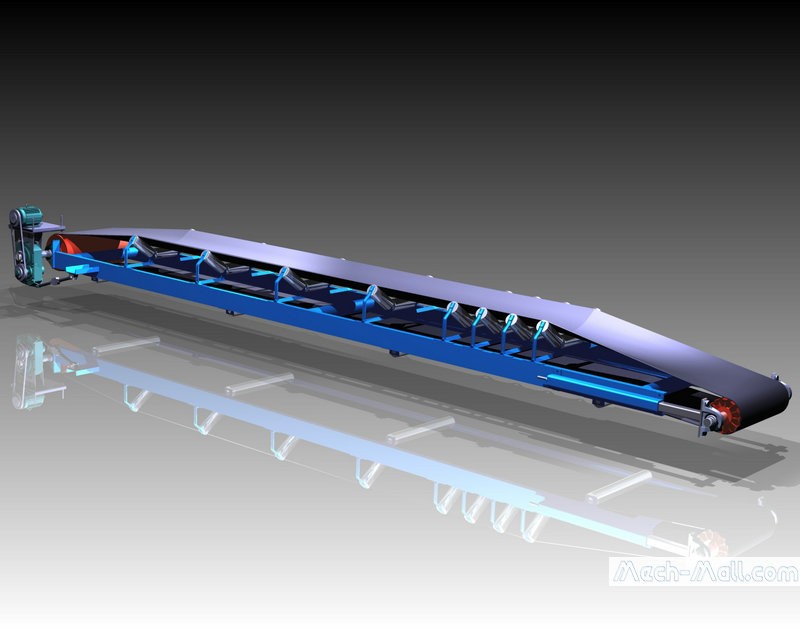

Belt Conveyor

■ Product’s Introduction

Belt conveyor have large conveying capacity, simple structure, convenient maintenance, low cost, highly optimized for general use etc. Widely used in mining, metallurgy, coal, transport, hydropower and other departments for conveying bulk material or formed articles. According to the requirements of the transportation process, it can be single conveyor, also can be many sets of combination or combined with other conveyor, turn into a horizontal or inclined conveying system. Work environment is generally -25℃-40℃,special environment, should adopt the corresponding protection measures. Conveying density is 500-2500kg/ m³ of various materials.

■ Principle of Work

In order to adapt to different using, it designed two kinds of driving device. One is open driver unit, is composed of electric motors and reducers. One is close driver unit, which uses motorized pulleys.The motor drives the driving rollers of the belt conveyor, and drives the roller by the strong belt advances. Materials are conveyed from the original place to the place where they are needed.

■ Technical Parameters

| Type | Belt Length (m) / Power (kw) | Speed (m/s) | Capacity (t/h) | ||

| TD-B400 | ≤12/2.2 | 12-20/2.2-4 | 20-25/3.0-7.5 | 1.25-2.0 | 30-60 |

| TD-B500 | ≤12/3 | 12-20/3-5.5 | 20-30/5.5-7.5 | 1.25-2.0 | 40-80 |

| TD-B650 | ≤12/4 | 12-20/4-5.5 | 20-30/5.5-11 | 1.25-2.0 | 80-120 |

| TD-B800 | ≤10/4 | 10-15/4-5.5 | 15-30/5.5-15 | 1.25-2.0 | 120-200 |

| TD-B1000 | ≤10/5.5 | 10-20/5.5-11 | 20-40/11-22 | 1.25-2.0 | 200-320 |

| TD-B1200 | ≤10/7.5 | 10-20/7.5-15 | 20-40/15-30 | 1.25-2.0 | 290-480 |